A Comprehensive Guide to Choosing the Right Metal Coating for Your Project

Choosing the right metal coating for your project is essential for ensuring the durability, appearance, and performance of your metal items. Whether you are working on a small DIY project or a large industrial task, this blog will help you understand the different types of metal coatings and how to choose the best one for your needs.

What is Metal Coating?

Metal coating is a process where a protective layer is applied to the surface of metal. This layer helps to protect the metal from rust, corrosion, and wear and tear. It also improves the appearance of the metal and can add other properties like electrical conductivity or non-stick surfaces.

Types of Metal Coatings

There are several types of metal coatings, each with its own benefits. Here are some of the most common types:

Paint Coating

Paint coatings are the most common type of metal coating. They are easy to apply and come in many colors. Paint provides a good level of protection against rust and can be used on many types of metal surfaces. However, paint may chip or peel over time, especially if the metal is exposed to harsh weather conditions.

Powder Coating

Powder coating is a dry finishing process where a powder made of resin and pigment is sprayed onto the metal surface. The coated metal is then baked in an oven, which makes the powder melt and form a hard, durable finish.

Powder coating is more durable than paint and is resistant to chipping, scratching, and fading. It is ideal for outdoor furniture, bicycles, and automotive parts.

Galvanizing

Galvanizing involves coating the metal with a layer of zinc. This process protects the metal from rust and corrosion. There are two main types of galvanizing: hot-dip galvanizing and electro-galvanizing.

Hot-dip galvanizing involves dipping the metal into molten zinc, while electro-galvanizing uses an electrical current to apply the zinc. Galvanizing is commonly used for steel beams, fences, and outdoor structures.

Anodizing

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of metal parts. This coating is very durable and can be dyed in various colors. Anodizing is often used for aluminum products, such as window frames, kitchen appliances, and electronics. It provides good corrosion resistance and a decorative finish.

Electroplating

Electroplating is a process that uses an electrical current to coat a metal object with a thin layer of another metal, such as chrome, gold, or silver. This coating improves the appearance and resistance to corrosion and wear and tear. Electroplating is used for jewelry, car parts, and electronics.

Step-by-Step Guide to Choosing the Right Metal Coating

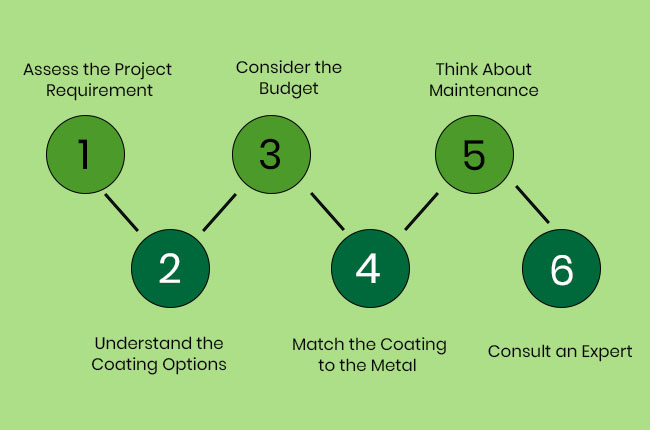

Here is a simple step-by-step guide to help you choose the right metal coating for your project:

Step 1: Assess the Project Requirements

First, evaluate what your project needs. Determine the type of metal you are using and what it will be exposed to. Ask yourself questions like:

Will the metal be indoors or outdoors?

Will it face high temperatures or moisture?

Does it need to look decorative or just functional?

What type of weather conditions can it be sustained?

Step 2: Understand the Coating Options

Read about the different types of coatings available. Learn about their benefits and drawbacks. Knowing the pros and cons of each type will help you make a better decision.

Step 3: Consider the Budget

Decide how much you are willing to spend. Some coatings are more affordable, while others offer better durability and appearance but at a higher cost.

Step 4: Match the Coating to the Metal

Not all coatings work well with all metals. For example, anodizing is mainly used for aluminum, while galvanizing is best for steel. Ensure that the coating you choose is suitable for the metal you are using.

Step 5: Think About Maintenance

Consider how much maintenance the coated metal will need. Some coatings, like powder coating, require less maintenance compared to paint, which may need touch-ups over time.

Step 6: Consult an Expert

If you are unsure, consult with a professional. They can provide advice based on your specific project needs and help you choose the best coating.

Conclusion

Choosing the right metal coating for your project involves considering the environment, durability, appearance, and cost. By understanding the different types of metal coatings and their benefits, you can make an informed decision that will ensure your project is successful and long-lasting.

Whether you choose paint, powder coating, galvanizing, anodizing, or electroplating, each option offers unique advantages that can enhance the performance and look of your metal items