Design

In the design process we create a plan for the production of the sheet metal product which includes determining the size, shape of the product and any other specific details and features that it will have.

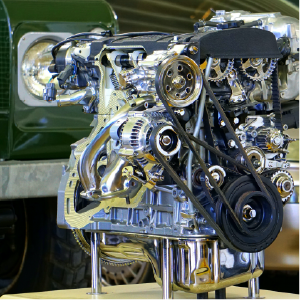

Sheet Metal Fabrication is the process of turning flat sheets of metal into custom parts and structures.It involves cutting, bending, welding and assembling the metal using various tools and techniques. It enables custom-built components and product design that results in high-precision parts required for many industries from construction to the healthcare industry.

In the design process we create a plan for the production of the sheet metal product which includes determining the size, shape of the product and any other specific details and features that it will have.

We create a sample physical model to test the feasibility or functionality of the design, and evaluating the fit and finish of the product before the full-scale manufacturing begins.

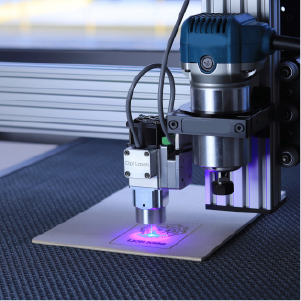

We utilize a high-energy laser beam that melts, vaporises or burns away the material to produce the desired product part with a high level of detail and smooth finish with CNC laser machines.

Bending or forming involves deforming a sheet of metal into a specific shape or geometry. In VmakeU Global Pvt. Ltd we perform these processes manually or with the help of specialized CNC machines.

It involves a combination of the above processes to form the metal into the desired shape and create the finished product. We also include welding and fasteners fixing.

The process that is used to protect the metal to increase longevity and improve its appearance. There are a variety of coatings like paint, powder coating, galvanizing etc to choose from depending on the needs.