Copper vs. Aluminium Busbars: How to Choose Which One Is Right for Your Application

When it comes to electrical power distribution, busbars play a crucial role. They carry electricity within switchgear, panel boards, and busway enclosures. Choosing the suitable material for your busbars is essential for the efficiency and reliability of your electrical system. The two primary materials used for busbars are copper and aluminium. Each has its advantages and disadvantages. This blog will explore these differences to help you decide which material is best for your application.

What Are Busbars?

Busbars are metallic strips or bars used to conduct electricity. They are used in electrical panels, switchboards, and substations to distribute power. The primary materials for busbars are copper and aluminium because they are good conductors of electricity.

Copper Busbars

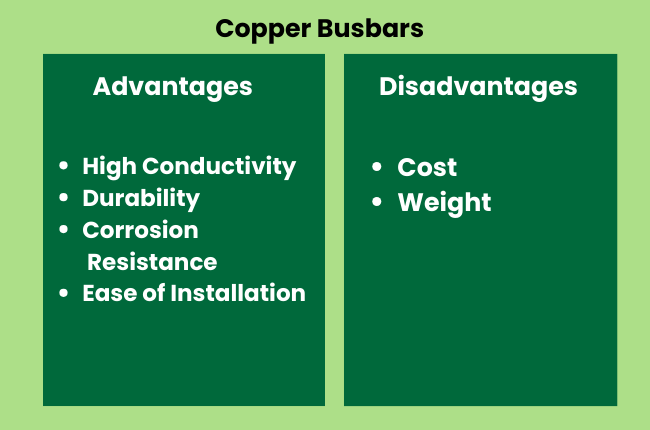

Advantages

High Conductivity: Copper has excellent electrical conductivity. This means it can carry more current than aluminium for the same size.

Durability: Copper is highly durable and can withstand high temperatures without losing strength.

Corrosion Resistance: Copper naturally resists corrosion, making it suitable for harsh environments.

Ease of Installation: Copper busbars are easy to install because they are more flexible and require less support.

Disadvantages

Cost: Copper is more expensive than aluminium. This can be a significant factor, especially for large projects.

Weight: Copper is heavier than aluminium, making handling and installation more difficult, especially in large systems.

Aluminum Busbars

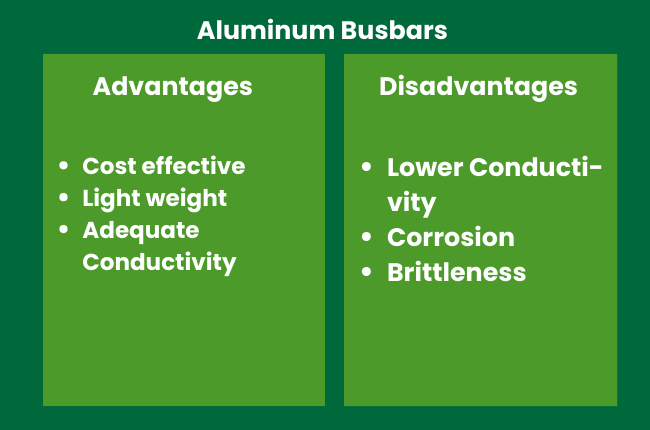

Advantages

Cost-Effective: Aluminum is generally cheaper than copper, which can result in significant cost savings, especially for large installations.

Lightweight: Aluminum is lighter than copper, making it easier to handle and install.

Adequate Conductivity: Although not as conductive as copper, aluminium conductivity is sufficient for many applications.

Disadvantages

Lower Conductivity: Aluminum has lower electrical conductivity than copper. This means you need a larger aluminium busbar to carry the same current as a copper busbar.

Corrosion: Aluminum is more prone to corrosion, especially when exposed to moisture. However, this can be mitigated by proper coating and maintenance.

Brittleness: Aluminum is more brittle and less flexible than copper, making it harder to work with.

How to Choose Between Copper and Aluminum Busbars

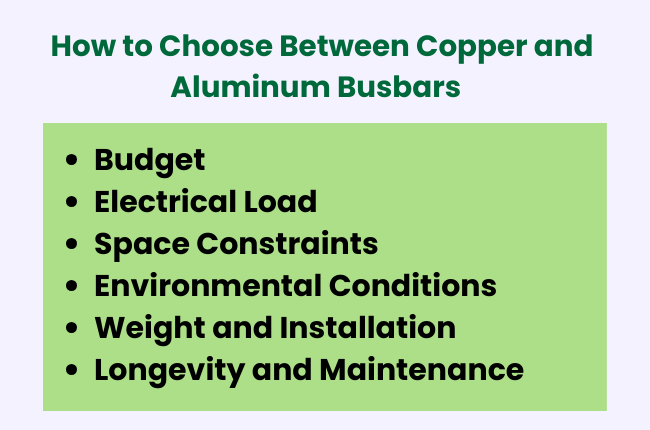

When deciding between copper and aluminium busbars, consider the following factors:

1. Budget

If you have a limited budget, aluminium busbars might be the better choice due to their lower cost. For large projects, the cost difference can be substantial.

2. Electrical Load

Copper busbars are more suitable for applications that require high current loads because of their superior conductivity. If your system needs to carry a lot of current, copper might be the better option despite the higher cost.

3. Space Constraints

Because copper is more conductive, you can use smaller busbars to carry the same amount of current. Copper busbars can save valuable space in your panels or enclosures if space is a concern.

4. Environmental Conditions

Consider the environment where the bus bars will be used. If the busbars are exposed to harsh conditions, such as high humidity or corrosive chemicals, copper's natural corrosion resistance might be the better choice.

5. Weight and Installation

If weight is critical, such as in portable systems or applications where the busbars need to be moved frequently, aluminium's lightweight nature can be advantageous.

6. Longevity and Maintenance

Copper busbars require less maintenance and have a longer lifespan due to their durability and corrosion resistance. Copper is a better option if you are looking for a long-term solution with minimal maintenance.

Wrapping Up!

Both copper and aluminium busbars have their strengths and weaknesses. Their choice depends on various factors, including budget, electrical load, space, environmental conditions, and maintenance requirements.

Copper busbars are ideal for applications requiring high conductivity and durability and where cost is not a primary concern. On the other hand, aluminium busbars are an excellent alternative for projects with budget constraints or where weight is a significant consideration.

By carefully considering these factors, you can choose the suitable material for your busbars, ensuring efficiency, reliability, and cost-effectiveness for your electrical power distribution system.