Electrical Industry Solutions: Providing Reliable Sheet Metal Components for Power Systems

The electrical industry plays a crucial role in our daily lives, powering homes, businesses, and essential services. A vital part of this industry is the production of reliable sheet metal components, which are vital for the safety and efficiency of power systems. This blog will explore how the electrical industry provides reliable sheet metal components for power systems, their importance, and the innovations making them better.

What are Sheet Metal Components?

Sheet metal components are made from thin, flat pieces of metal. These components are used in various electrical applications, including enclosures, panels, and brackets. They are essential for protecting electrical equipment, ensuring safety, and maintaining system stability.

Importance of Reliable Sheet Metal Components

Safety: Reliable sheet metal components protect electrical systems from external damage. They prevent accidents by keeping hazardous electrical parts covered and away from contact.

Durability: High-quality sheet metal components can withstand harsh environmental conditions. They resist corrosion, high temperatures, and physical impacts, ensuring long-term performance.

Efficiency: Well-designed components help in the efficient distribution of electrical power. They minimize energy loss and enhance the overall performance of power systems.

Compliance: Using reliable components ensures compliance with safety and industry standards. This is important for both legal reasons and for maintaining a good reputation.

Types of Sheet Metal Components in Power Systems

Enclosures: These are boxes or cabinets that house electrical equipment. They protect the equipment from dust, moisture, and mechanical damage.

Panels: Panels hold and organize electrical components like switches, relays, and circuit breakers. They make maintenance and troubleshooting easier.

Brackets: Brackets support and hold various electrical components in place. They ensure that everything stays secure and organized.

Busbars: These are strips of metal used to conduct electricity within a switchboard, distribution board, or other electrical apparatus. They help in the efficient distribution of power.

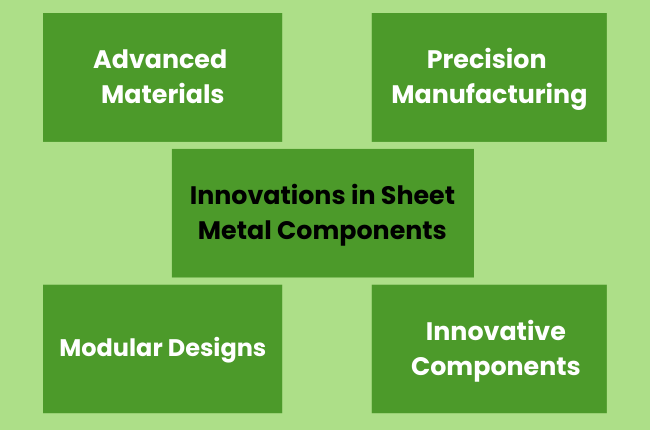

Innovations in Sheet Metal Components

The electrical industry is continuously innovating to improve the reliability and performance of sheet metal components. Some of these innovations include:

Advanced Materials: New materials like stainless steel, aluminum alloys, and coated metals offer better resistance to corrosion, wear and tear. They enhance the durability of components.

Precision Manufacturing: Modern manufacturing techniques like laser cutting and CNC machining allow for precise and consistent production of sheet metal components. This ensures high quality and reduces the risk of defects.

Modular Designs: Modular components can be easily assembled and customized. This flexibility allows for quicker installation and easier upgrades or repairs.

Innovative Components: Integrating sensors and intelligent technologies in sheet metal components can provide real-time monitoring and diagnostics. This helps in predictive maintenance and reduces downtime.

Role of Sheet Metal Fabricators

Sheet metal fabricators are specialized companies that design and produce sheet metal components. Their role is critical in ensuring the reliability and quality of these components. They use advanced machinery and techniques to cut, bend, and assemble metal sheets into precise shapes and sizes.

Critical Considerations for Choosing Sheet Metal Components

Material Quality: Choose components made from high-quality materials that suit the specific application and environmental conditions.

Design Specifications: Ensure that the design of the components meets the requirements of the power system. Consider factors like load capacity, heat dissipation, and ease of installation.

Manufacturer Reputation: Work with reputable manufacturers known for their quality and reliability. Check for certifications and customer reviews.

Cost-effectiveness: While quality should never be compromised, consider the cost-effectiveness of the components. Look for a balance between price and performance.

Wrapping Up!

Reliable sheet metal components are essential for power systems' safe and efficient operation. They provide protection, enhance performance, and ensure compliance with safety standards. The electrical industry continues to innovate, bringing advanced materials, precision manufacturing, and intelligent technologies to improve these components. By choosing high-quality sheet metal components and working with reputable fabricators, we can ensure the reliability and longevity of our power systems.

The importance of reliable sheet metal components cannot be overstated. The unsung heroes keep our power systems running smoothly, safely, and efficiently. As technology advances, we can look forward to even more innovative solutions in the electrical industry, ensuring a brighter and more reliable future for all.