Exploring the Role of CAD Software in Sheet Metal Design and Prototyping

Sheet metal is a cornerstone in many industries. From automotive to aerospace, construction to consumer goods, sheet metal is everywhere. But how do engineers and designers turn raw metal sheets into functional parts and products? The answer lies in Computer-Aided Design (CAD) software. This powerful tool has revolutionized how we approach sheet metal design and prototyping. Let’s explore how CAD software plays a crucial role in this process.

What is CAD Software?

CAD stands for Computer-Aided Design. It is software used by engineers, architects, and designers to create precise drawings and models of products and structures. Before CAD, all designs were made by hand on paper. This process was time-consuming and prone to errors. CAD software makes designing faster, more accurate, and much easier to modify.

Why is CAD Important in Sheet Metal Design?

Precision and Accuracy: Sheet metal parts need to fit together perfectly. Even a tiny mistake can lead to parts that do not fit or work as intended. CAD software allows designers to create extremely accurate models of their parts. They can specify exact dimensions and tolerances, ensuring that the final product will be just right.

Efficiency: Designing sheet metal parts by hand can take a lot of time. With CAD, designers can work much faster. They can quickly create and modify designs, test different ideas, and see how parts will fit together. This speed is crucial in industries where time is money.

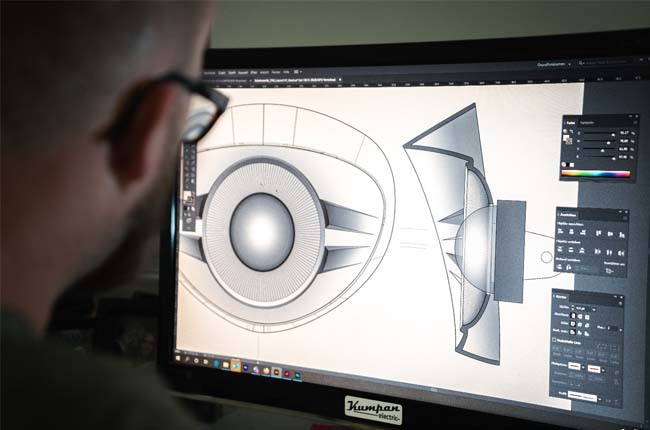

Complex Designs: Some sheet metal parts are very complex, with intricate shapes and features. Drawing these by hand would be nearly impossible. CAD software can handle these complexities easily. Designers can create and visualize even the most intricate parts.

Simulation and Testing: Before a part is made, it is important to test it. Will it be strong enough? Will it fit with other parts? CAD software can simulate these conditions. It can show how a part will behave under different stresses and loads. This testing can catch problems early, before any metal is cut.

The Prototyping Process

Once a design is complete, the next step is prototyping. A prototype is a sample or model of a product used to test the design. Prototyping is a critical step in the development process, and CAD software plays a big role here too.

Creating Prototypes: The precise models created in CAD can be used to make prototypes. These models can be fed directly into machines that cut and shape the sheet metal. This process is called CNC (Computer Numerical Control) machining. CNC machines follow the exact specifications from the CAD model, creating a perfect prototype.

Iterating on Designs: Often, the first prototype is not perfect. Designers might need to make changes and try again. CAD makes this easy. They can quickly modify their designs and create new prototypes. This iterative process helps refine the design until it is just right.

Cost-Effective: Making mistakes can be expensive, especially with materials like metal. CAD reduces the risk of costly errors. By catching problems early and allowing for quick changes, it saves both time and money.

Real-World Applications

Let’s look at some real-world examples of CAD in sheet metal design and prototyping.

Automotive Industry: Car manufacturers use CAD to design every part of a vehicle. From the body panels to the smallest brackets, everything is designed in CAD. This ensures that all parts fit together perfectly and perform well.

Aerospace: In the aerospace industry, precision is crucial. Aircraft parts must meet strict safety standards. CAD software helps engineers design these parts with high precision. It also allows for thorough testing and simulation, ensuring that the parts will perform under the extreme conditions of flight.

Consumer Electronics: Gadgets like smartphones and laptops have many sheet metal components. These parts need to be strong, lightweight, and precisely made. CAD helps designers create these parts efficiently and accurately.

Final Thoughts!

CAD software has transformed the sheet metal design and prototyping process. It allows for precise, efficient, and complex designs. It makes prototyping faster and less costly. From cars to airplanes to consumer electronics, CAD is at the heart of modern sheet metal design.

As technology advances, we can expect CAD software to become even more powerful, further revolutionizing how we create and build with sheet metal.