Innovations in Custom Sheet Metal Fabrication: Trends Shaping the Industry

Custom sheet metal fabrication is a crucial part of modern manufacturing. It involves shaping metal sheets into various products used in many industries. From car parts to kitchen appliances, sheet metal is everywhere. Over time, the way we make these metal products has changed. Let's see the trends that are shaping the future of custom sheet metal fabrication.

Advanced Technology

In the past, cutting and shaping metal sheets was done by hand. But now, we have advanced machines called CNC (Computer Numerical Control) machines. These machines use computers to precisely cut and shape metal sheets according to specific designs.

They are much more accurate and faster than doing it by hand. This helps reduce waste and makes production faster and more efficient.

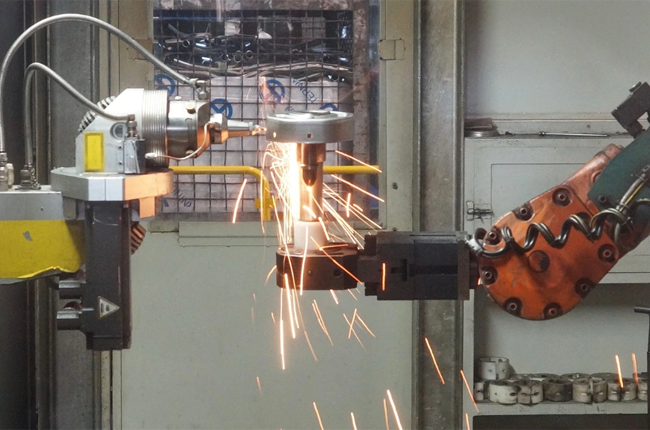

Automation

Automation is a big change in the sheet metal fabrication industry. Robots are now doing many tasks that were once done by people. They can weld, handle materials, and even assemble products. This not only speeds up production but also makes the workplace safer for people.

Sustainability

Being kind to the environment is important today. That's why many manufacturers are using recycled materials in sheet metal fabrication. Recycled metal sheets, like aluminum and steel, are becoming more popular.

Also, machines are being made to use less energy and produce fewer emissions, helping to protect our planet.

Digitalization

Digital technology is changing the way we make things. With the Internet of Things (IoT), machines can talk to each other and to us. We can monitor and control the production process in real-time from anywhere using computers or smartphones.

This makes production more efficient and helps us catch problems early.

3D Printing

3D printing, also known as additive manufacturing, is a new way of making things. Instead of cutting away material like traditional methods, 3D printing builds up layers of material to create a product.

This allows for more complex and unique designs that were impossible before. It's still developing, but it has huge potential to change how we make things.

Material Science

New materials and coatings are being developed all the time. These materials make products stronger, lighter, and more resistant to things like rust. They also make products look better and last longer.

With these technologies, manufacturers can create products that perform better and are more environmentally friendly.

Artificial Intelligence

Artificial intelligence (AI) is making its way into sheet metal fabrication. AI can analyze data to make production more efficient. It can predict when machines might break down and fix problems before they happen. This saves time and money and keeps production running smoothly.

Conclusion

Custom sheet metal fabrication is changing fast. From advanced machines and robots to using recycled materials and digital technology, these trends are shaping the industry's future. By embracing these changes, manufacturers can make better products, protect the environment, and stay ahead in today's competitive market.

Whether it's making cars, appliances, or even airplanes, custom sheet metal fabrication is at the heart of it all, and it's evolving to meet the challenges of tomorrow.