Sheet Metal Fabrication: Innovations Driving Efficiency in Manufacturing

Sheet metal fabrication is a cornerstone industry. Sheet metal is an important material in a wide range of products we use daily, from automotive parts to aerospace components, household appliances to intricate machinery. However, as demand for precision and efficiency rises, so does the need for innovation in the sheet metal fabrication industry. In this blog post, we'll look at some of the latest innovations that are increasing efficiency in sheet metal fabrication and revolutionizing the way products are manufactured.

Automation and Robotics

Automation has transformed many industries, including sheet metal fabrication. Advanced robotics can now perform tasks that were previously labor-intensive and time-consuming, resulting in significant improvements in efficiency and accuracy.

Robotic arms equipped with a variety of tools can perform repetitive tasks like cutting, bending, and welding with unrivaled accuracy and speed. These robots can work around the clock, reducing production times and costs while ensuring consistent quality.

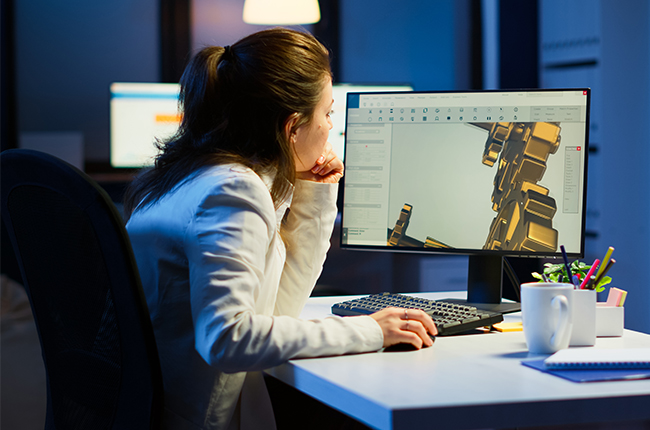

Emerging Software

In Sheet Metal Fabrication, new technologies are making things easier and faster. Software like CAD, SolidWorks, CATIA, UG, and ProE help a lot. They help designers make better plans and models of metal parts. These programs are easy to use, and they help save time. They let engineers test their designs before making them.

This means fewer mistakes and less waste of materials. So, companies can make things quicker and cheaper. These software programs are changing how things are made with metal, making the process more efficient and better for everyone.

Additive Manufacturing (3D Printing)

Additive manufacturing, also known as 3D printing, has opened new possibilities for sheet metal fabrication. While traditional methods involve cutting and shaping a metal sheet, additive manufacturing creates parts layer by layer with materials such as metal powder.

This technology enables the creation of extremely complex geometries, which would be difficult or impossible to achieve using traditional methods. It also reduces material waste and enables rapid prototyping, which speeds up the product development cycle.

Laser Cutting and CNC Machining

Laser cutting and Computer Numerical Control (CNC) machining have become essential tools for modern sheet metal fabrication. Laser cutting uses a focused laser beam to precisely cut through metal sheets, providing unparalleled speed and accuracy.

CNC machining, on the other hand, employs computer-controlled machinery to remove material from a workpiece and shape it into the desired form. These technologies allow for intricate parts with tight tolerances, eliminating the need for manual labor and decreasing production times.

Smart Manufacturing and IoT Integration

The proliferation of smart manufacturing and the Internet of Things (IoT) is transforming traditional factories into interconnected, data-driven environments. By incorporating sensors and monitoring systems into fabrication equipment, manufacturers can collect real-time data on machine performance, production rates, and quality metrics.

This data can be used to improve processes, avoid downtime, and anticipate maintenance requirements. Using IoT technologies, manufacturers can improve productivity, quality, and efficiency in sheet metal fabrication.

Conclusion

Innovation is driving the evolution of sheet metal fabrication. From advanced robotics and automation to advanced software and additive manufacturing, these technologies are reshaping the industry, making it faster, more precise, and less expensive than ever before.

As manufacturers continue to embrace these innovations, we can expect to see further increases in productivity, quality, and sustainability, ushering in a new era of sheet metal manufacturing. Whether it's in automotive, aerospace, electronics, or any other industry, the future of manufacturing is bright, thanks to these innovative advances.