The Fundamentals of Machining: Understanding the Basics for Beginners

Machining is an important process in manufacturing. It involves shaping and cutting materials to make parts and products. If you’re new to machines, this blog will help you understand the basics.

What is Machining?

Machining is a process used to remove material from a workpiece to get the desired shape and size. It is done using various tools and machines. The material can be metal, plastic, wood, or composites.

Common Machining Processes

There are several machining processes, but the most common ones are:

Turning: This process uses a lathe. The workpiece rotates while a cutting tool removes material. It is used to create cylindrical parts.

Milling: This process uses a milling machine. The cutting tool rotates while the workpiece is stationary. It is used to create flat surfaces, slots, and complex shapes.

Drilling: This process uses a drill press or a milling machine. The cutting tool, a drill bit, creates holes in the workpiece.

Grinding: This process uses a grinding wheel. It removes material to produce a smooth surface finish.

Key Components of Machining

Several key components are involved in machining:

Workpiece: This is the material that is being shaped or cut. It can be a piece of metal, plastic, wood, or other materials.

Machine Tool: This is the machine that holds the cutting tool and the workpiece. It provides the motion needed to cut the material.

Cutting Tool: This is the tool that removes material from the workpiece. It can be a drill bit, a milling cutter, a grinding wheel, or other types of cutting tools.

Coolant: This is a fluid used to cool the cutting tool and workpiece during machining. It also helps to remove chips and reduce friction.

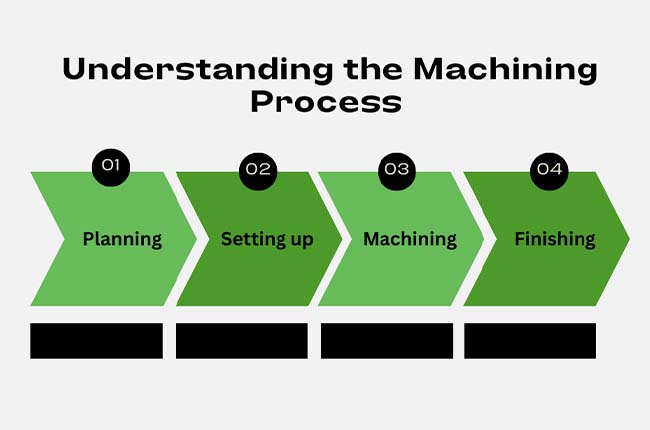

Understanding the Machining Process

The machining process involves several steps:

Planning: Before the machine starts, you need to plan the process. This includes selecting the right machine tool, cutting tool, and workpiece material. You also need to determine the cutting speed, feed rate, and depth of cut.

Setting Up: This involves setting up the machine tool and securing the workpiece. The cutting tool is also installed and aligned.

Machining: During machining, the cutting tool removes material from the workpiece. The machine tool controls the movement and speed of the cutting tool.

Finishing: After machining, the part may need finishing. This can include grinding, sanding, or polishing to achieve the desired surface finish.

Important Machining Terms

Here are some important terms you should know:

Cutting Speed: This is the speed at which the cutting tool moves. It is usually measured in surface feet per minute (SFM) or meters per minute (m/min).

Feed Rate: This is the distance the cutting tool moves per revolution of the workpiece. It is usually measured in inches per revolution (IPR) or millimeters per revolution (mm/rev).

Depth of Cut: This is the thickness of the material removed in one pass of the cutting tool. It is usually measured in inches or millimeters.

Chip: This is the material removed from the workpiece during machining. It is also called a swarf.

Safety in Machining

Safety is very important in machining. Here are some safety tips:

Always wear safety glasses, gloves, and hearing protection.

Keep the area around the machine clean and free of clutter.

Always follow the manufacturer’s instructions for operating the machine.

Use the right cutting tools for the job and ensure they are sharp and in good condition.

Keep hands and clothing away from moving parts of the machine.

Wrapping Up!

Machining is a fundamental process in manufacturing that involves shaping and cutting materials to create parts and products. By understanding the basics of machining, beginners can get a good start in this field.

Always remember to prioritize safety and follow proper procedures to ensure successful machining operations