The Future of Sheet Metal Fabrication: Emerging Technologies and Trends

In the world of manufacturing, sheet metal fabrication is a big deal. From making car parts to building structures, it’s a vital process. But like everything else, it's evolving. Let's peek into the future and see what's coming up!

Automation and Robotics

Imagine a factory where robots do most of the work. That's what's coming in sheet metal fabrication. These robots can bend, cut, and weld with precision. They work faster and more accurately than humans. This means quicker production times and fewer errors.

Green Sheet Metal Solutions

Environmental concerns drive the development of sustainable sheet metal fabrication technologies. This includes the adoption of eco-friendly materials, energy-efficient processes, and recycling initiatives aimed at reducing the carbon footprint of sheet metal manufacturing.

IoT and Data Analytics

The Internet of Things (IoT) is about connecting devices to the internet. In sheet metal fabrication, this means machines talking to each other. They can share data about production, maintenance needs, and even predict when something might go wrong. This helps factories run more smoothly and saves money on repairs.

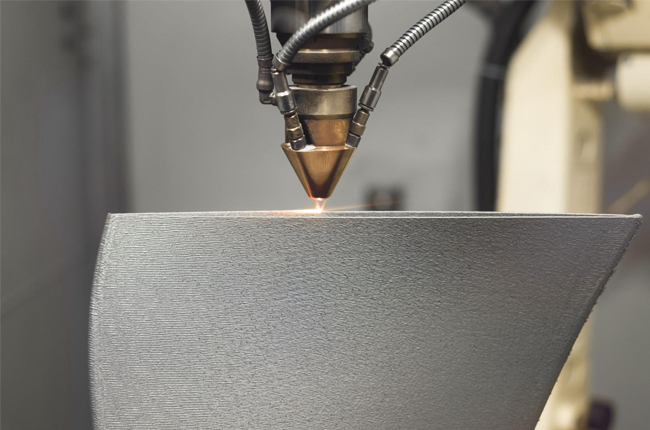

Laser Cutting

Laser cutting is already common, but it's getting better. The new lasers are faster and more precise. They can cut thicker metal and do it with less energy. This makes production quicker and more eco-friendly.

Nanotechnology

Nanotechnology is all about working with super tiny things. In sheet metal fabrication, it means creating coatings or materials that are incredibly strong and resistant to wear. This makes products last longer and perform better.

Sustainable Practices

The future is green, and sheet metal fabrication is no exception. Manufacturers are finding ways to reduce waste and energy use. They're recycling scrap metal and using eco-friendly materials. This not only helps the planet but also saves money in the long run.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR are not just for gaming. In sheet metal fabrication, they're used for training and design. Workers can learn new skills in a virtual environment. Engineers can visualize designs before they're made. This saves time and reduces mistakes.

Artificial Intelligence (AI)

AI is making its mark in almost every industry, including sheet metal fabrication. Machines can learn from past experiences and improve processes. They can optimize production schedules and even design products themselves. This leads to more efficient factories and better products.

Smart Factories

The future of sheet metal fabrication is smart factories. These factories are fully connected and automated. Machines communicate with each other and with the people running the show. They adjust production in real-time based on demand and supply chain data. This makes manufacturing faster, cheaper, and more flexible.

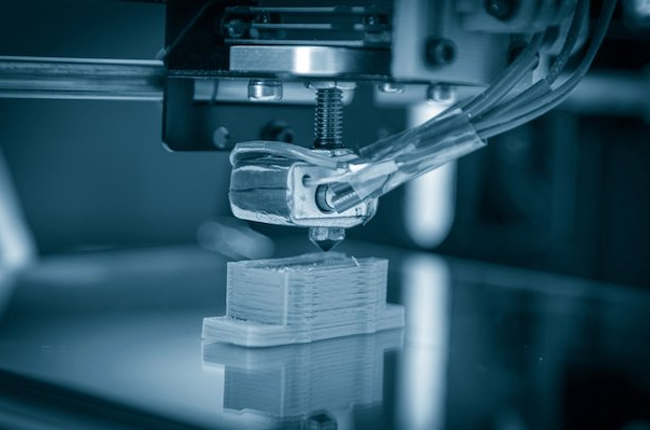

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is gaining ground in sheet metal fabrication. It involves building parts layer by layer from digital designs. This method reduces waste and allows for more intricate designs. It's especially useful for making prototypes and custom parts.

Final Thoughts

The future of sheet metal fabrication is bright and full of possibilities. With improvements in automation, 3D printing, IoT, and more, the industry is set to become faster, more efficient, and more sustainable.

Whether it's creating intricate designs or mass-producing parts, the technologies and trends shaping sheet metal fabrication are sure to revolutionize the way we build things. Exciting times lie ahead for this essential manufacturing process!